Industrial environments demand physical resilience where lighting solutions face accidental impacts, vibration stresses, and installation pressures. When housing materials lack sufficient rigidity or reinforcement, deformation occurs, compromising seal integrity and internal component protection. For authentic 40w Triproof Light performance, structural integrity must be engineered into the solution rather than treated as an afterthought. True durability emerges when material selection and geometric design work synergistically to maintain protective enclosure stability under real-world stresses.

Material science plays a crucial role in maintaining form stability. Advanced composites resist permanent deformation while retaining impact absorption qualities. Housing geometries incorporate strategic reinforcement patterns that distribute mechanical loads away from critical sealing surfaces. Crucially, mounting systems integrate stress dispersion features that prevent localized pressure points during installation or maintenance. These considerations separate robust solutions from those merely appearing substantial while compromising protection essentials.

Validation separates credible manufacturers from superficial claims. Progressive facilities subject samples to repeated stress simulations mimicking years of industrial exposure. Real-world installations in high-traffic facilities provide performance benchmarks over extended periods. For the responsible 40w Triproof Light creator, such evidence outweighs theoretical specifications. They bridge the gap between laboratory conditions and practical durability - proving true resilience requires designing for unintended forces rather than just passing basic certification tests.

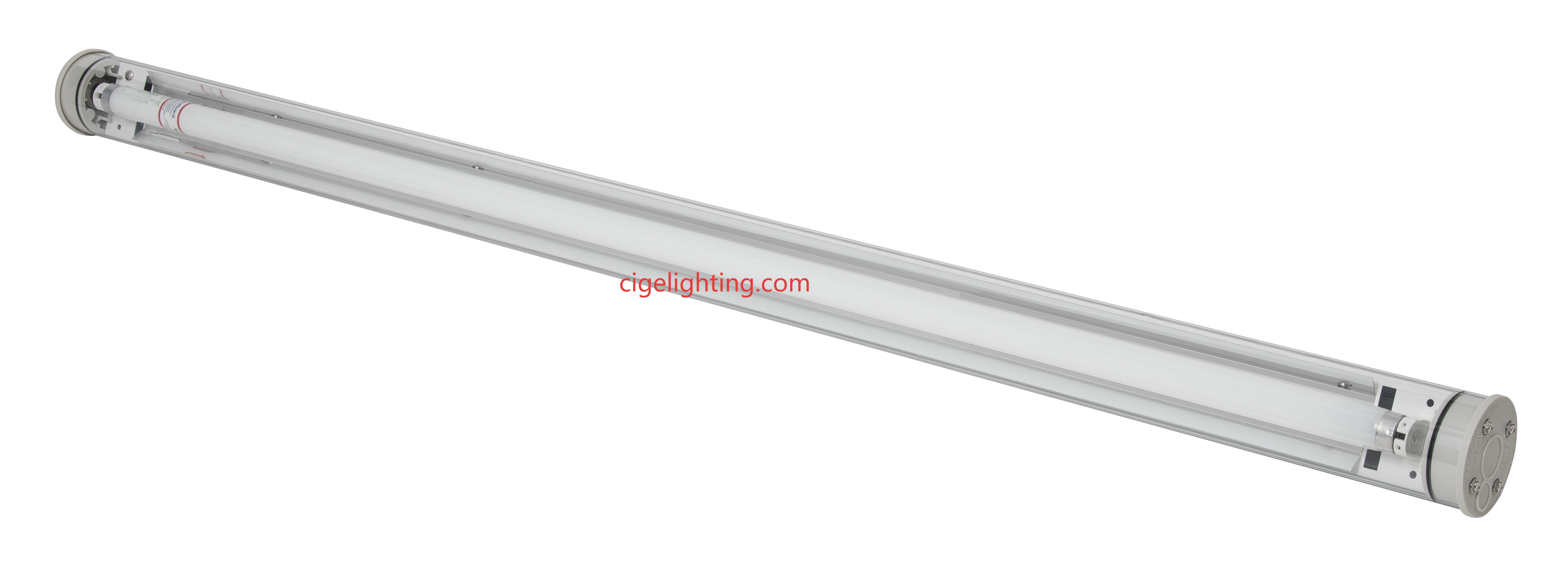

Cigelighting engineers structural excellence. Our 40w Triproof Light solutions incorporate advanced reinforcement systems. Partner with us for luminaires where physical integrity matches environmental protection claims.Click https://www.cigelighting.com/product/ to reading more information.