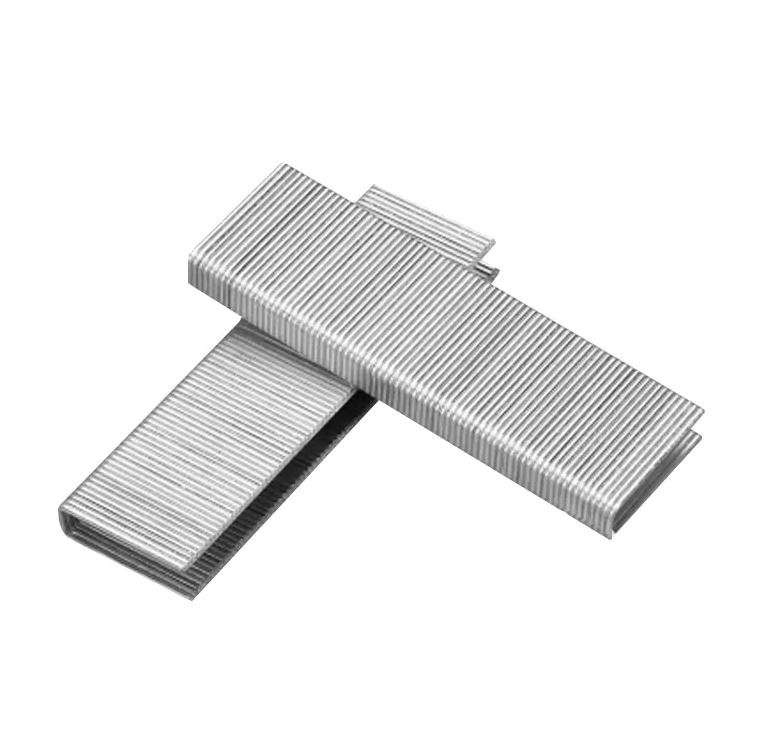

Heavy Wire Staples are typically associated with applications that require enhanced fastening strength and material compatibility. Understanding where these staples are used helps clarify why they occupy a specific position within the fastener market.

One major application area is industrial woodworking. Furniture manufacturing often involves large panels, thick frames, and load-bearing joints. Heavy Wire Staples help maintain joint alignment and reduce movement during assembly and usage. Their wire thickness supports consistent penetration in dense wood materials.

In building and renovation projects, Heavy Wire Staples are used for securing roof sheathing, wall panels, and flooring layers. These components must remain fixed under daily use, vibration, and environmental changes. Staples with heavier wire provide a more secure hold compared with lighter fastening options.

Packaging operations rely on Heavy Wire Staples for assembling crates and pallets used in shipping. Wood-based packaging structures must withstand stacking pressure and movement. Thicker staples help ensure that boards remain connected, reducing the likelihood of damage to goods.

Outdoor structures also benefit from the properties of Heavy Wire Staples. Decks, fences, and exterior wooden frameworks are subject to moisture and temperature variation. Staples manufactured with corrosion-resistant coatings support longer service periods without compromising fastening stability.

Tool compatibility further contributes to the practical use of Heavy Wire Staples. They are commonly designed to work with pneumatic and manual staplers used in industrial and construction environments, allowing consistent installation across multiple applications.

In conclusion, Heavy Wire Staples are used where material thickness, load requirements, and environmental exposure intersect. By addressing these conditions effectively, Heavy Wire Staples continue to support a wide range of structural and outdoor fastening tasks.