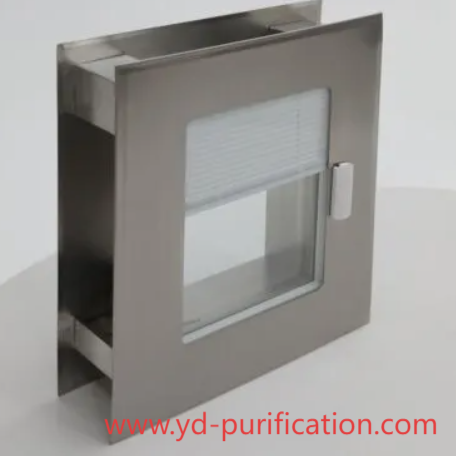

In advanced manufacturing and laboratory environments,Yuanda Clean Room Window is a key element for maintaining controlled conditions and ensuring operational transparency. As facility standards evolve and contamination risks become critical, how can precision windows enhance efficiency and safety in modern cleanrooms?

Airflow regulation is a primary concern in any controlled space. Even small gaps or improper seals can allow particles to enter sensitive areas, compromising product quality or experimental accuracy. Professionally engineered windows provide airtight sealing and stable pressure maintenance, allowing staff to monitor processes safely while protecting the environment. Selecting durable, corrosion-resistant materials ensures long-term performance and minimal maintenance.

Hygiene and cleaning efficiency are essential. Smooth surfaces prevent dust accumulation and support strict environmental protocols. Scratch-resistant glass and reinforced frames withstand frequent use without degradation. This combination of durability and cleanliness sustains operational integrity across laboratories, pharmaceutical facilities, and electronics production areas.

Noise insulation and vibration control are subtle but impactful. Sensitive processes can be affected by external disturbances. Well-designed windows reduce vibration transfer and mitigate noise, maintaining consistent conditions and allowing continuous observation without interruption.

Visibility and natural lighting are additional factors influencing workflow. Transparent, anti-glare glass supports supervision while maintaining isolation. Strategically placed windows enable staff to assess operations without entering restricted zones, improving safety and operational efficiency simultaneously.

Integration with environmental monitoring systems adds further value. Sensors positioned near windows can detect pressure, temperature, or humidity changes, enabling quick adjustments and reducing manual inspection. This integration ensures operational standards remain consistent and reliable.

Ergonomics and ease of maintenance remain important. Windows that open safely for inspection or cleaning reduce physical strain and save time. Modular or customizable designs allow facilities to adjust configurations to meet specific operational requirements without extensive reconstruction.

Energy efficiency is a key consideration. High-quality insulation and airtight construction minimize energy loss, supporting temperature and humidity control while aligning with sustainability practices. Durable materials and low-maintenance design contribute to continuous, reliable operations.

Safety compliance is a priority. Laminated or tempered glass protects personnel from accidental impact, while designs adhere to fire and workplace safety regulations. Thoughtful design balances personnel protection with environmental control and operational efficiency.

Yd-purification provides Clean Room Window solutions that combine precision, durability, and hygiene. Their systems integrate advanced engineering with practical application, helping facilities maintain transparency, stability, and compliance. Professionals interested in high-quality cleanroom solutions can explore Clean Room Window at https://www.yd-purification.com/product/ to see how these systems support modern industrial operations efficiently.